- Cut thickness of material

- Cut width of material

- Coil material

- Apply adhesives

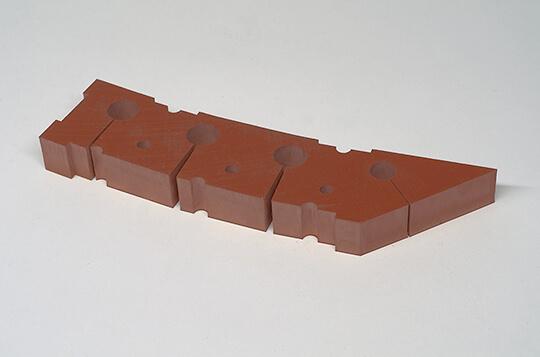

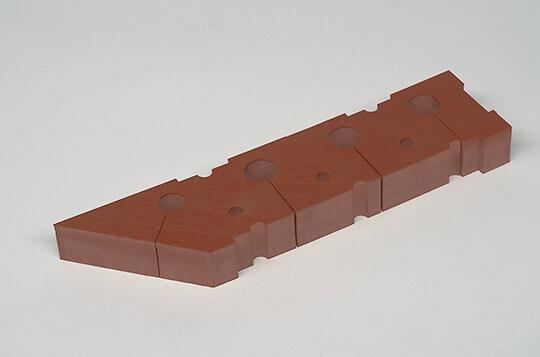

Water Jet Cutting

Our waterjet machines allow CNC cutting on a wide range of materials. The water jet can cut at a rate of 150 inches/per minute. Our machines have extremely tight tolerances and allow for the importing of CAD files for programming. These machines can be used for prototyping as well as low to medium volume production.

We generally use a .005” jewel which results in an excellent finish on completed parts. Waterjet cutting also allows us to process parts where holes are very close to the wall of the part where traditional die-cutting simply will not work. It also allows us to process thick material. For example, we can fabricate rubber parts up to 1” thick and foam parts up to 2” thick.

Advantages of Water Jet Cutting

- Clean and precise cutting

- No compression distortion

- Tight tolerances

- No tooling cost

- Quick turn-around of parts

- Prototyping different materials, sizes, patterns, etc.

- Ability to tightly nest parts to maximize material yield

- Minimal clearance between holes or other features

Explore More Capabilities

- Minimal set-up

- High accuracy/finish

- Ideal for prototypes

- Minimal set-up

- High accuracy/finish

- Ideal for prototypes

- Efficient in processing different materials.

- Can accommodate for long run times and large part sizes.

- Equipment also has milling capabilities.

- Rotary die-cutting

- Hydraulic presses

- Punch presses

- Manual presses

- Programmable travel head presses

- From roll or sheet stock

- Minimal set-up

- Large parts - 36" x 54"

- Low tool cost

- Cuts solid rubber and sponge rubber

- Allows for production of OD / ID parts

- Efficient and High-Speed

- Excellent alternative to molding.

- Ability to vulcanize extruded rubber.

- Ability to vulcanize sponge rubber profiles.

- Accurate to .00005"

- 27 x 27 bed

- Used for all first and last piece inspection

- Accurate to .00005"

- 27 x 27 bed

- Used for all first and last piece inspection

- Cut thickness of material

- Cut width of material

- Coil material

- Apply adhesives