- Cut thickness of material

- Cut width of material

- Coil material

- Apply adhesives

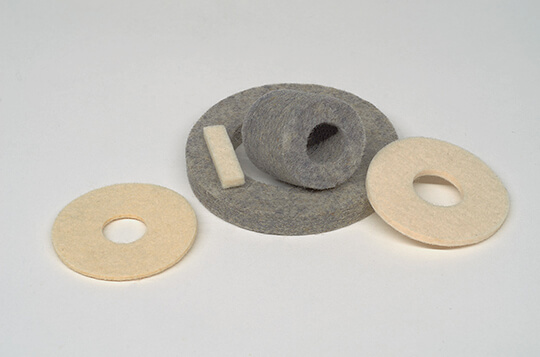

Wool & Synthetic Felt Gaskets

Felt remains a popular material used in certain gasketing applications. Felt is supplied in both wool and synthetic options. Wool felt is made from pressing premium wool fibers together. This type of product is commonly referred to as “pressed” felt.

- Flame resistance

- Material remains unchanged with continued exposure to many oils

- High strength and excellent wear properties

- Excellent insulator against sound, temperature and vibration

- It does not fray or come apart

Benefits of Wool Felt

In addition to gasketing, wool felt gaskets are also commonly used as wipers and around filter applications. Wool felt is supplied in various SAE standards ranging from F-1 through F-26. These various factors dictate the wool content, density and other physical properties of the felt.

Felt also comes in a wool blend. This material consists of wool and synthetic fibers. The material is generally a lower grade than pure wool felt and is generally used in packaging applications.

Lastly felt is provided in pure synthetic options. Generally, this material is made from polyester or other synthetic fibers that are pressed together or bonded together using heat. Like wool felt, this material comes in various densities. In addition, manufacturers can add certain coatings to increase flame resistance or add certain properties specific for applications.

Get Started with Your Custom Part

Contact UsSynthetic Felt

Since synthetic felt is made from various man-made materials, manufacturers can substitute different materials at different proportions to achieve certain weight, air flow, etc specific to a desired end product.

Synthetic felt is generally used in the same applications as wool felt, but synthetic felt can withstand higher operating temperatures. Synthetic felt options are typically less expensive than wool.

Featured Capabilities

- Minimal set-up

- High accuracy/finish

- Ideal for prototypes

- Minimal set-up

- High accuracy/finish

- Ideal for prototypes

- Efficient in processing different materials.

- Can accommodate for long run times and large part sizes.

- Equipment also has milling capabilities.

- Rotary die-cutting

- Hydraulic presses

- Punch presses

- Manual presses

- Programmable travel head presses

- From roll or sheet stock

- Minimal set-up

- Large parts - 36" x 54"

- Low tool cost

- Cuts solid rubber and sponge rubber

- Allows for production of OD / ID parts

- Efficient and High-Speed

- Excellent alternative to molding.

- Ability to vulcanize extruded rubber.

- Ability to vulcanize sponge rubber profiles.

- Accurate to .00005"

- 27 x 27 bed

- Used for all first and last piece inspection

- Accurate to .00005"

- 27 x 27 bed

- Used for all first and last piece inspection

- Cut thickness of material

- Cut width of material

- Coil material

- Apply adhesives