- Cut thickness of material

- Cut width of material

- Coil material

- Apply adhesives

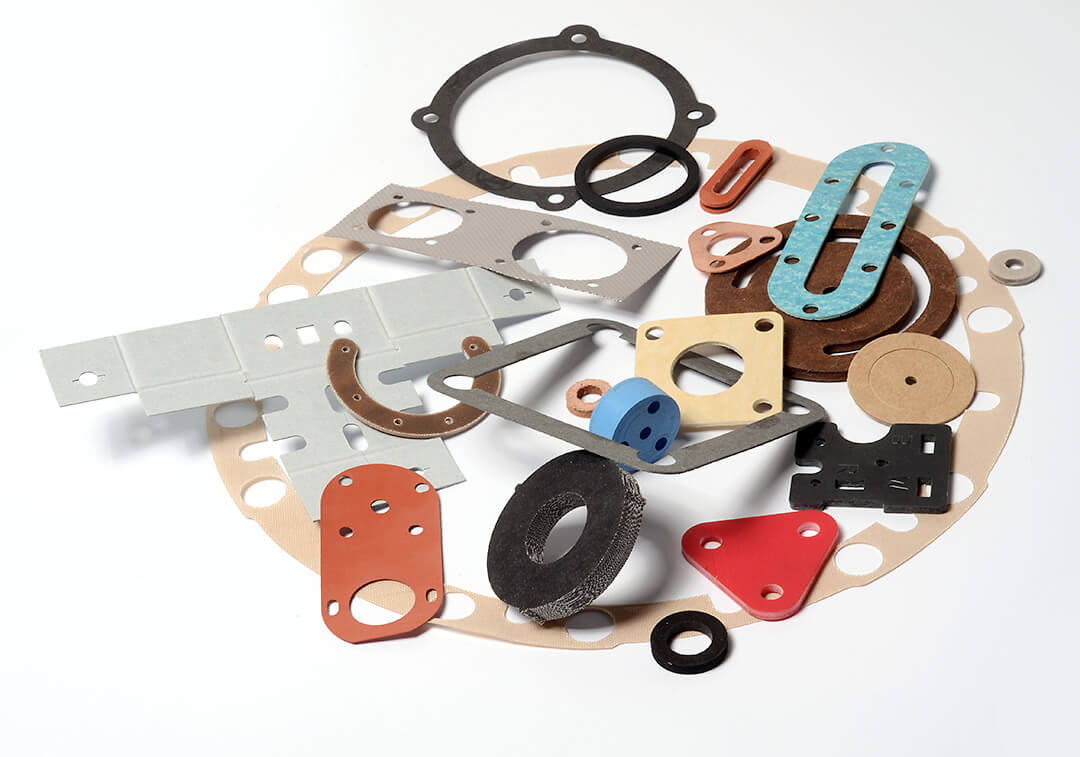

Gasket Material Selection Guide

The guide will assist you in gasket material selection, gasket design and gasket application. Selecting the right gasket design and material is critical to the effective operation of a reliable joint. It involves taking into account a wide variety of application parameters such as function, temperature, fluid or gas, pressure, UV & Ozone, EMI/RFI requirements and other considerations such as FDA, NSF or WRAS requirements.

Nitrile (NBR), Natural gum rubber (NR), Styrene-butadiene (SBR), Ethylene Propylene (EPDM), Butyl (NR), Carboxylated Nitrile (XNBR), Neoprene (CR), Silicone (VQM), Fluorocarbon (FKM), Polyacrylate (ACM), Urethane (AU) (EU), Fluorosilicone (FVMQ), Ethylene Acrylic (AEM), Hydrogenated Nitrile (HNBR)

Material Properties & Performance include: Min/Max temperature range, Compression set, Properties, Chemical resistance, Relative cost

Polyimide (PI) (Kapton), Polyetheretherketone (PEEK), Polytetrafluoroethylene (PTFE) (Teflon), Polyamide (PAI) (Nylon), Polyetherimide (PEI) (Ultem), Phenolic, Acrylonitrile-Butadiene-Styrene (ABS), High-Density Polyethylene (HDPE), Polyester (PET), Polycarbonate (PC) (Lexan), Polypropylene (PP), Polyvinyl Chloride (PVC), Polystyrene (PS), Acetal Homopolymer (Delrin), Ultra High Molecular Weight Polyethlyne (UHMWPE), Polyethlyne (PE), Low-Density Polyethylene (LDPE)

Material Properties & Performance include: Continuous operating temperature, Chemical resistance, UV resistance, Compressive strength, Coefficient of friction, Dielectric strength, Shore D hardness, Compressive modulus, Relative cost.

S.A.E. F-1 (16R1), S.A.E. F-2 (16R2), S.A.E. F-3 (16R3), S.A.E. F-5 (12R1), S.A.E. F-6 (12R2), S.A.E. F-7 (12R3), S.A.E. F-10 (9R1), S.A.E. F-11 (9R2), S.A.E. F-12 (9R3), S.A.E. F-13 (9R4), S.A.E. F-15 (9R5), S.A.E. F-26 (8R5), S.A.E. F-50 (16R1X), S.A.E. F-51 (16R3X) , S.A.E. F-55 (12R3X)

S.A.E specifications include: Color, Density, Applications

Additional Materials Reviewed

Cork, Cork & Rubber, Foam, Sponge, Pressure Sensitive Adhesive,Vegetable Fiber, Vulcanized Fiber, Fish Paper and Insulating materials

Descriptive information:

Composition, Applications, Chemical Resistance and Performance

Mechanical elements to be considered for optimizing a joint are also reviewed. They include clamp load, compression set, stress relaxation, surface finish, flange stiffness, bolt size, bolt grade, bolt head style and bolt pattern.

Get Started with Your Custom Part

Contact UsExplore Capabilities

View All Capabilities

- Minimal set-up

- High accuracy/finish

- Ideal for prototypes

- Minimal set-up

- High accuracy/finish

- Ideal for prototypes

- Efficient in processing different materials.

- Can accommodate for long run times and large part sizes.

- Equipment also has milling capabilities.

- Rotary die-cutting

- Hydraulic presses

- Punch presses

- Manual presses

- Programmable travel head presses

- From roll or sheet stock

- Minimal set-up

- Large parts - 36" x 54"

- Low tool cost

- Cuts solid rubber and sponge rubber

- Allows for production of OD / ID parts

- Efficient and High-Speed

- Excellent alternative to molding.

- Ability to vulcanize extruded rubber.

- Ability to vulcanize sponge rubber profiles.

- Accurate to .00005"

- 27 x 27 bed

- Used for all first and last piece inspection

- Accurate to .00005"

- 27 x 27 bed

- Used for all first and last piece inspection

- Cut thickness of material

- Cut width of material

- Coil material

- Apply adhesives