- Cut thickness of material

- Cut width of material

- Coil material

- Apply adhesives

EMI Insulating & Shielding Materials

EMI stands for electromagnetic interference. Electromagnetic energy can come from many sources and without proper protection, can result in the failure of certain electrical systems. EMI shielding gaskets can protect electronic systems against electromagnetic interference.

To achieve proper EMI shielding, a product typically needs to use a certain amount of metal. Common metals used as EMI shielding materials include silver, aluminum and copper.

Electrically Conductive Silicone & Fluorosilicone

This is probably the most common and widely used EMI shielding material. These products offer the benefits of silicone (high operating temp, thermal stability, flame retardant, good chemical resistance) with added metal particles to create EMI protection.

Solid Silicone used to create EMI Shielding

Extremely conductive, but high cost

Generally least expensive, but less shielding effectiveness than graphite or silver

Very conductive, but less cost than pure silver

In certain instances, conductive silicone products can also be provided with a fabric layer insert that provides further EMI protection as well as added stability.

Very conductive, but less cost than pure silver

Moderate shielding at less cost than silver products

Depending on the application, we can supply a conductive adhesive on one of both sides of a part. Both acrylic and rubber options exist for conductive PSA.

Get Started with Your Custom Part

Contact UsSponge Rubber Material

Certain applications require the use of a softer material than solid silicone. In these cases, products are made with silicone sponge or other sponge rubber and other metal additives. These products can be used in circuit boards or other applications where compression is needed or air gaps are a concern.

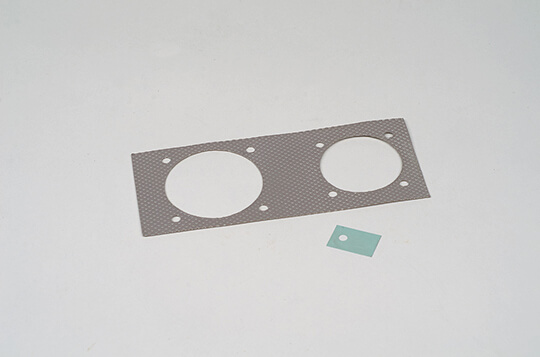

Copper, Silver & Aluminum Foils

Sometimes these metals are offered by themselves in very thin forms as an EMI material. These materials are directed for specific EMI shielding purposes. They can be offered alone or used as a wrap to enclose sponge rubber or other material.

Featured Capabilities

View All Capabilities

- Minimal set-up

- High accuracy/finish

- Ideal for prototypes

- Minimal set-up

- High accuracy/finish

- Ideal for prototypes

- Efficient in processing different materials.

- Can accommodate for long run times and large part sizes.

- Equipment also has milling capabilities.

- Rotary die-cutting

- Hydraulic presses

- Punch presses

- Manual presses

- Programmable travel head presses

- From roll or sheet stock

- Minimal set-up

- Large parts - 36" x 54"

- Low tool cost

- Cuts solid rubber and sponge rubber

- Allows for production of OD / ID parts

- Efficient and High-Speed

- Excellent alternative to molding.

- Ability to vulcanize extruded rubber.

- Ability to vulcanize sponge rubber profiles.

- Accurate to .00005"

- 27 x 27 bed

- Used for all first and last piece inspection

- Accurate to .00005"

- 27 x 27 bed

- Used for all first and last piece inspection

- Cut thickness of material

- Cut width of material

- Coil material

- Apply adhesives