- Cut thickness of material

- Cut width of material

- Coil material

- Apply adhesives

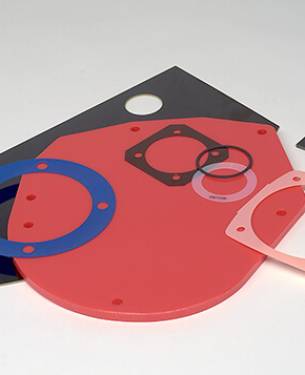

Gasket Material Selection

Our extensive experience with a wide variety of gasket materials enables us to be able to work with you to determine the optimum material for your application.

Excelsior offers a wide variety of gasket materials to meet the needs of any job and is a preferred distributor for a number of material manufacturers. We maintain a large inventory of materials and are always adding new and high-temperature gasket materials to meet customer needs.

Cloth-Inserted Rubber

Material DetailsRubber is also commonly used with cloth or fabric-inserts. Common fabrics include cotton, nylon, polyester and fiberglass. These products will have 1 or more layers of fabric throughout the thickness of the rubber. Generally, the fabric is added to increase stability where mechanical fastening is necessary.

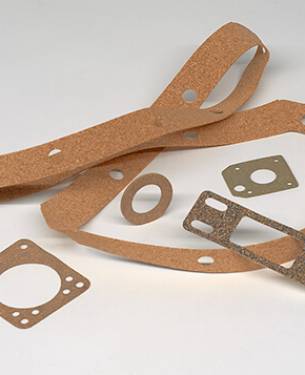

Corks & Cork Rubber

Material DetailsCork and rubber gaskets are commonly used in sealing flanges where there is contact with oil, fuel or natural gas and where bolting pressure is somewhat low. Both cork and cork/rubber gaskets are excellent when mating surfaces have possible imperfections or don't perfectly mate as they will conform to the surfaces.

- Cork composition

- Cork - friction

- Cork / Buna-N

- Cork & nitrile, neoprene or silicone

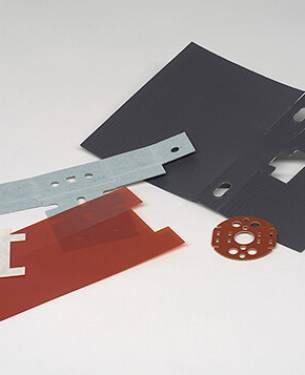

Electrical Insulating Materials

Material DetailsGaskets are commonly used in and around electrical applications. These electrical insulation materials are used to prevent or restrict the flow of electrical current; prevent electrical arcing; prevent electrical conductors from contacting unwanted objects; and other general electrical insulation applications.

EMI Insulating & Shielding Materials

Material DetailsEMI stands for electromagnetic interference. Electromagnetic energy can come from many sources and without proper protection, can result in the failure of certain electrical systems. EMI shielding gaskets can protect electronic systems against electromagnetic interference.

- Metal impregnated silicone

- Metal foils

FDA Approved Rubber

Material DetailsThe FDA regulates materials that are in contact with food or beverages during processing, packaging or storage. We offer a number of different materials that are certified to meet FDA standards.

Felts

Material DetailsFelt remains a popular material used in certain gasketing applications. Felt is supplied in both wool and synthetic options. Wool felt is made from pressing premium wool fibers together. This type of product is commonly referred to as “pressed” felt.

- Flame resistance

- Material remains unchanged with continued exposure to many oils

- High strength and excellent wear properties

- Excellent insulator against sound, temperature and vibration

- It does not fray or come apart

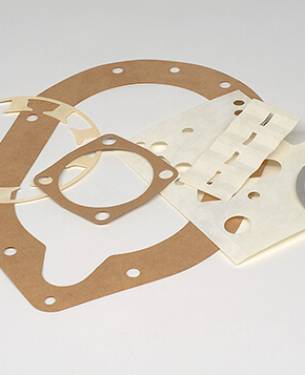

Fiber and Paper

Material DetailsFiber-based gaskets are one of the most broadly used categories of products. Fiber products can offer a very wide range of benefits and fit a wide range of applications.

- Barrier Paper

- Cellulose

- Ceramic fiber

- Fishpaper

- Nomex

- Vegetable fiber (Detroiter)

- Vulcanized fiber - black, grey & red

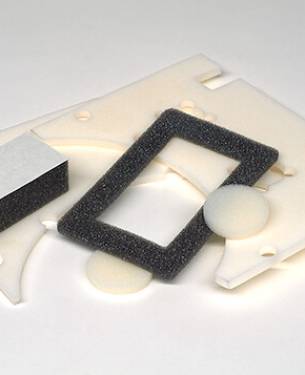

Foam

Material DetailsPolyurethane foam is a softer, open-cell foam that allows air and liquid to penetrate through the foam. Polyethylene foam is a more firm closed-cell foam that is more dense and rigid.

- Convoluted

- Cross-linked

- Filter

- Hydrophilic

- Melamine

- Polyether

- Polyester

- Polyethylene

- Polyurethane

- PVC

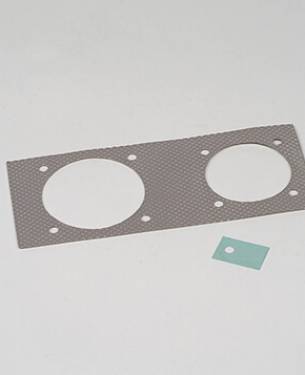

Metal

Material DetailsUnlike synthetic materials, certain metals can have a significantly longer useful life. In addition, certain products contain both synthetic materials and metals. Examples include metal-impregnated silicone used for EMI and metal/fiber blends used for exhaust and engine systems. Excelsior works with metal gasket material including:

- Aluminum

- Copper

- Flexible Graphite

- Steel, including shim stock

We process other materials that have a thin layer of metal inserted into gap pads and fiber blends. These metal materials are used for electrical applications and automotive exhaust or engine applications.

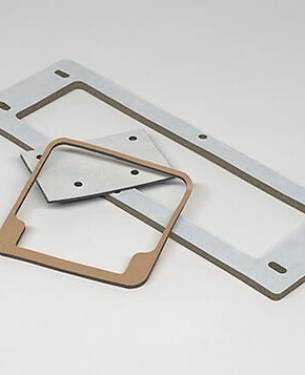

Non-Asbestos Compressed & Beater Mix Additions

Material DetailsThere is a broad range of engineered materials used for gasketing that are referred to as compressed sheet or non-asbestos. Generally, these materials are made with certain fibers (ie Aramid fiber) and other fillers with a rubber binder. Users will choose a rubber binder suitable for their application.

- Many brands and styles available

Other Gasket Material

Material DetailsExcelsior, Inc. offers a number of other materials to give you more options for your gasket manufacturing needs.

- Teflon Coated Fiberglass

- Grafoil / Flexible Graphite

- Mica

- AMS, FDA, NSF, Mil Spec and UL listed

- Nomex/Kapton laminates

Plastics

Material DetailsPlastic gaskets are durable and resistant to corrosion and an alternative to synthetic materials and metal gaskets. Plastic gasket benefits include lightweight, low friction with excellent sealing and insulating properties. Plastic material is versatile when manufacturing and can accommodate for many application types.

Pressure Sensitive Adhesive

Material DetailsPressure Sensitive Adhesive (PSA) is commonly used throughout gasket applications. PSA can be used from a temporary means of holding a product in place during assembly to a more long-term permanent manner in which to bond 1 item to another. The most common types of adhesives used in gasketing applications are acrylic based and rubber based products. These products can be offered in "transfer" or "double coated" options.

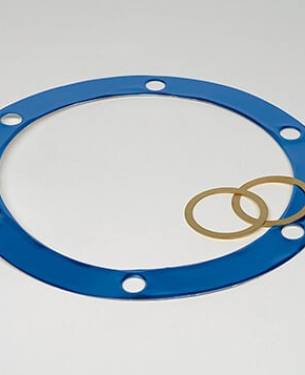

Solid Rubber

Material DetailsRubber is probably the most widely used gasket material. Rubber is offered in many different styles and grades to meet many applications’ needs. In addition, rubber is commonly available “off the shelf” in most styles, grades and thicknesses.

Synthetic rubbers are generally made from petroleum-based by-products. Alternatively, natural rubber is derived from latex from Rubber trees which are found in Thailand and Indonesia.

Closed-Cell Sponge Rubber

Material DetailsClosed cell sponge rubber gaskets use chemicals and heat to expand the material and create a “soft” or sponge rubber. Sponge rubber is generally sold by density or firmness. The primary types of solid rubber are also used to create sponge rubber. Sponge rubber is much more compressible than solid rubber and carries many of the benefits of solid rubber.

- EPDM sponge

- Neoprene sponge

- Neo / EPDM . SBR sponge

- PVC / Nitrile sponge

- Silicone sponge

- Viton sponge

Material Selection Guide

Material DetailsThe guide will assist you in gasket material selection, gasket design and gasket application. Selecting the right gasket design and material is critical to the effective operation of a reliable joint. It involves taking into account a wide variety of application parameters such as function, temperature, fluid or gas, pressure, UV & Ozone, EMI/RFI requirements and other considerations such as FDA, NSF or WRAS requirements.

Explore Capabilities

View All Capabilities

- Minimal set-up

- High accuracy/finish

- Ideal for prototypes

- Minimal set-up

- High accuracy/finish

- Ideal for prototypes

- Efficient in processing different materials.

- Can accommodate for long run times and large part sizes.

- Equipment also has milling capabilities.

- Rotary die-cutting

- Hydraulic presses

- Punch presses

- Manual presses

- Programmable travel head presses

- From roll or sheet stock

- Minimal set-up

- Large parts - 36" x 54"

- Low tool cost

- Cuts solid rubber and sponge rubber

- Allows for production of OD / ID parts

- Efficient and High-Speed

- Excellent alternative to molding.

- Ability to vulcanize extruded rubber.

- Ability to vulcanize sponge rubber profiles.

- Accurate to .00005"

- 27 x 27 bed

- Used for all first and last piece inspection

- Accurate to .00005"

- 27 x 27 bed

- Used for all first and last piece inspection

- Cut thickness of material

- Cut width of material

- Coil material

- Apply adhesives