- Cut thickness of material

- Cut width of material

- Coil material

- Apply adhesives

Solid Rubber

Solid Rubber

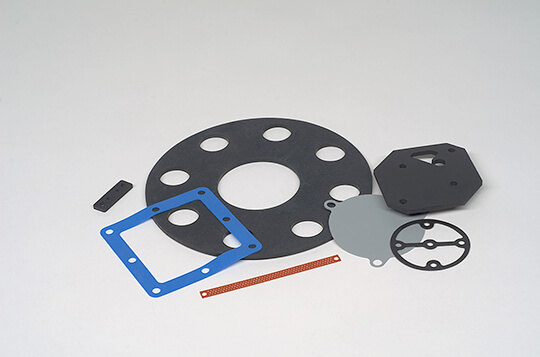

Custom, high-quality gaskets from Excelsior start with the right material. While there are many mediums available for creating your components, solid rubber gaskets stand out as durable and dynamic options. Explore the applications, types, and other features of this material today to see if it’s the right option for your gaskets.

Applications of Solid Rubber

We can manufacture durable synthetic and natural solid rubber products in a range of thicknesses, operating temperatures, and shapes. The solid rubber gasket material used can also affect its characteristics and recommended applications. Here are some example uses for solid rubber:

- Seals: Solid rubber creates a firm seal between two materials, keeping out moisture, air, or dust from interior or exterior environments. The durability of solid rubber makes it a useful choice when one or both components are moving parts.

- Trims and Extrusions: Edging materials made of solid rubber act as a seal while also protecting equipment from direct impacts and abrasions.

- Gaskets: Two static components can also enjoy a leak-free connection using solid rubber.

- Shock Absorbers: Direct impact can cause excessive shock in a piece of equipment, so solid rubber is often employed to reduce the damage of shock and vibration.

Solid rubber, while capable of withstanding extreme shock and vibration, doesn’t absorb them as efficiently as foam rubber. Solid rubber lacks the air cushioning effect of foam rubber.

Environments That Use Solid Rubber

Many connections of two components that shouldn’t leak can use solid rubber gaskets. These versatile gaskets are used to connect water lines, exhaust pipes, and air vents. Applications can use them to prevent air or liquids from escaping around the following items:

- Industrial Tanks

- Engine Blocks

- Exterior Doors

- Frames

- Fittings

These are just a few examples of the many areas where solid rubber used for gaskets can provide a mechanical seal. While there are some heat-related restrictions to consider, solid rubber is generally versatile enough to be used in most environments.

Industries Served

At Excelsior, we use solid rubber materials to provide gaskets for applications like yours. Here are examples of industries where solid rubber is a common solution for creating gaskets, seals, and shock absorbers:

- Food Processing

- Heavy Equipment

- Aerospace

- Automotive

- Oil, Gas, and Energy

Source Your Solid Rubber Gaskets Today

If you’re ready for reliable gaskets to seal your systems and power your products, consider sourcing solid rubber gaskets from Excelsior. Contact us today to learn more about this reliable medium, your options for solid rubber specifications, and how we can supply your facility with quality materials to meet your deadlines.

Common Solid Rubber Materials

Many rubber products are offered in standard commercial grades as well as high-grade. Generally, high-grade materials will have a higher percentage of the actual product (ie Nitrile) and may have a higher tensile strength and/or operating temperature range.

A list of the most commonly used rubbers and their characteristics are listed below.

Rubber |

Durometer |

Thickness |

Temperature Range |

Tensile Strength (PSI) |

Overview |

|

Butyl

|

40 - 80 |

.015-1.00 |

-40 - +225 |

1500 |

Excellent dielectric properties; low permeability to air and gases; moderate UV, ozone and oxidation resistance |

|

|

40 - 80 |

.015-1.00 |

-40 - +300 |

900 |

Excellent UV, ozone and oxidation resistance; also abrasion resistant |

|

|

40 - 80 |

.015-1.00 |

-40 - +300 |

900 |

FDA approved ingredients for use around food; white color |

|

|

40 - 80 |

.015-1.00 |

-40 - +300 |

900 |

NSF 61 approved for potable water applications |

|

Epichlorohydrin

|

60-70 |

.015-1.00 |

-40 - +250 |

1200 |

High-end rubber; excellent resistance to oil and grease; broad operating temp range; broad chemical compatibility |

|

Fluorosilicone

|

40 - 70 |

.015-1.00 |

-60 - +500 |

900 |

Excellent temp range; resistant to fuels and solvents; naturally resistant to ozone |

|

Gum Rubber / Natural Rubber |

40 |

.031 - 1.00 |

-60 - +220 |

2300 |

Good physical properties and low temp range; greater elongation than most rubbers; very resilient |

|

|

30 - 80 |

.015 - 1.00 |

-40 - +200 |

500 |

Low cost, general purpose material; moderate oil, grease, solvent and chemical resistance |

|

|

30 - 90 |

.015 - 1.00 |

-30 - +220 |

850 |

Widely used for its resistant to most oil, grease, water and hydraulic fluid. It is also compatible with certain chemicals |

|

|

50 - 70 |

.015 - 1.00 |

-30 - +220 |

800 |

FDA approved ingredients for use around food; white color |

|

SBR

|

60 - 80 |

.015 - 1.00 |

-40 - +220 |

500 |

Excellent abrasion, wear and water resistance; also resistant to certain chemicals |

|

|

30 - 80 |

.015 - 1.00 |

-80 - +450 |

600 |

Excellent high and low-temperature range; excellent ozone, oxidation and water resistance |

|

Silicone - Electrically Conductive

|

60 |

.015-1.00 |

-80 - +500 |

800 |

Protection against electrostatic discharge and EMI |

|

Silicone - FDA Approved

|

30 - 70 |

.015-1.00 |

-80 - +450 |

700 |

FDA approved ingredients for use around food |

|

Silicone - Fibreglass Reinforced

|

70 |

.015-1.00 |

-80 - +500 |

1300 |

Increased mechanical strength - up to 1300 PSI |

|

Silicone - Medical Grade

|

40 - 70 |

.015-1.00 |

-80 - +450 |

1200 |

USP Class Testing approved for use in medical devices |

|

Urethane

|

60 - 90 |

.015-1.00 |

-40 - +200 |

5000 |

Most abrasion resistance and strength while maintaining stability and flexibility |

|

|

50 - 80 |

.015-1.00 |

-20 - +400 |

1000 |

Higher-end material for broad use; good oil, fuel and chemical resistance; good aging properties; excellent UV, ozone and oxidation resistance |

- PSA available on all products. PSA is available in acrylic-based, rubber-based and acrylic-rubber blends. PSA also available in transfer and double-coated options.

- Standard thicknesses available in -.015, .031, .062, .093, .125, .187, .250, .312, .375, .500, .625, .750, 1.00.

- Custom and metric thicknesses also available

- Standard durometer for most rubber products: 30, 40, 50, 60, 70, 80, 90

Get Started with Your Custom Part

Contact Us

- Minimal set-up

- High accuracy/finish

- Ideal for prototypes

- Minimal set-up

- High accuracy/finish

- Ideal for prototypes

- Efficient in processing different materials.

- Can accommodate for long run times and large part sizes.

- Equipment also has milling capabilities.

- Rotary die-cutting

- Hydraulic presses

- Punch presses

- Manual presses

- Programmable travel head presses

- From roll or sheet stock

- Minimal set-up

- Large parts - 36" x 54"

- Low tool cost

- Cuts solid rubber and sponge rubber

- Allows for production of OD / ID parts

- Efficient and High-Speed

- Excellent alternative to molding.

- Ability to vulcanize extruded rubber.

- Ability to vulcanize sponge rubber profiles.

- Accurate to .00005"

- 27 x 27 bed

- Used for all first and last piece inspection

- Accurate to .00005"

- 27 x 27 bed

- Used for all first and last piece inspection

- Cut thickness of material

- Cut width of material

- Coil material

- Apply adhesives