- Cut thickness of material

- Cut width of material

- Coil material

- Apply adhesives

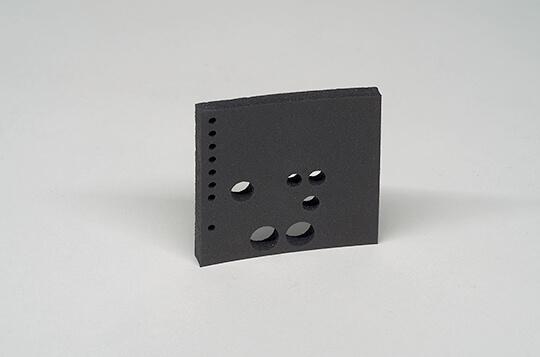

Laser Cut Gaskets

Our laser machines allow CNC cutting on a wide range of materials. Laser cutting is excellent for closed-cell foam and sponge rubber as well as certain plastics. We also use it to process certain fiber and paper materials. It results in a very clean finish and allows us to process intricate part designs. The machine has extremely tight tolerances and allow for the importing of CAD files for programming and can be used for prototyping as well as low to medium volume production.

Advantages of Laser Cutting

- Clean and precise cutting

- No compression distortion

- Tight tolerances

- No tooling cost

- Quick turn-around of parts

- Prototyping different materials, sizes, patterns, etc.

- Ability to tightly nest parts to maximize material yield

- Minimal clearance between holes or other features

Get Started with Your Custom Part

Contact UsWater Jet Cutting vs. Laser Cutting

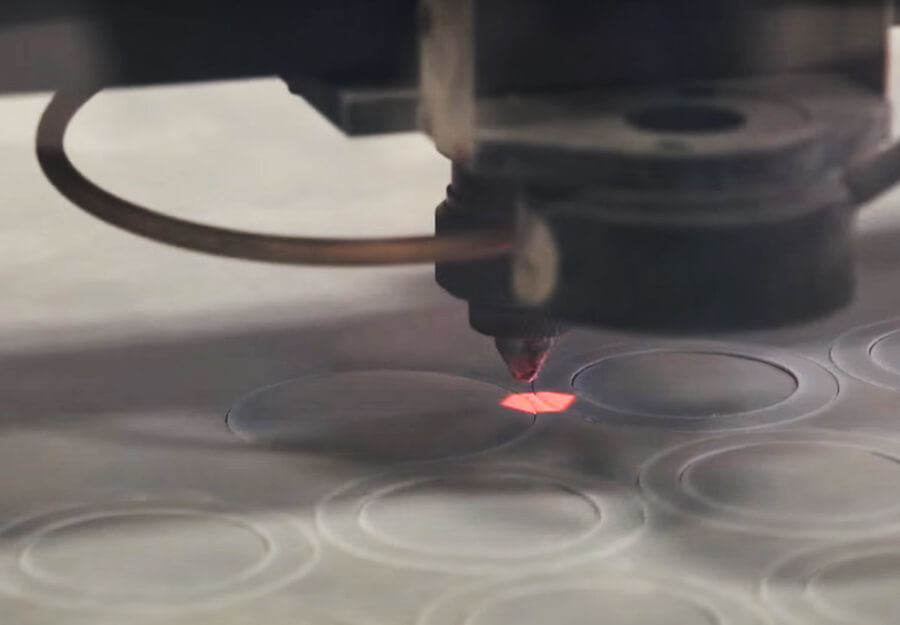

Water jet cutting uses technology that offers extremely clean and accurate cuts by forcing high-pressure water through a small nozzle (typically .005”). In our waterjet process, we do not use any abrasives in our machine, but rather pure water which is filtered multiple times before reaching the cutting head. Waterjet cutting is ideal for thick rubber (up to ¾”), certain plastics, compressed non-asbestos material, and parts where there is minimal clearance between holes or sides of a part.

Laser cutting is a clean and precise method of cutting gaskets. High-powered lasers are controlled by a computer-aided design (CAD) program to move and cut out the desired shapes. We use a CO2 laser, which gives us the ability to adjust the strength of the laser and speed of the cut to best suit the material being processed. Laser cutting is ideal for closed-cell materials, foams, certain plastics, polyester films, paper, and certain fibers. It is also ideal where there is minimal clearance between the holes of the sides of a part.

Both methods allow for tighter tolerances than traditional die cutting, generally +/- .005”.

Explore More Capabilities

- Minimal set-up

- High accuracy/finish

- Ideal for prototypes

- Minimal set-up

- High accuracy/finish

- Ideal for prototypes

- Efficient in processing different materials.

- Can accommodate for long run times and large part sizes.

- Equipment also has milling capabilities.

- Rotary die-cutting

- Hydraulic presses

- Punch presses

- Manual presses

- Programmable travel head presses

- From roll or sheet stock

- Minimal set-up

- Large parts - 36" x 54"

- Low tool cost

- Cuts solid rubber and sponge rubber

- Allows for production of OD / ID parts

- Efficient and High-Speed

- Excellent alternative to molding.

- Ability to vulcanize extruded rubber.

- Ability to vulcanize sponge rubber profiles.

- Accurate to .00005"

- 27 x 27 bed

- Used for all first and last piece inspection

- Accurate to .00005"

- 27 x 27 bed

- Used for all first and last piece inspection

- Cut thickness of material

- Cut width of material

- Coil material

- Apply adhesives