- Cut thickness of material

- Cut width of material

- Coil material

- Apply adhesives

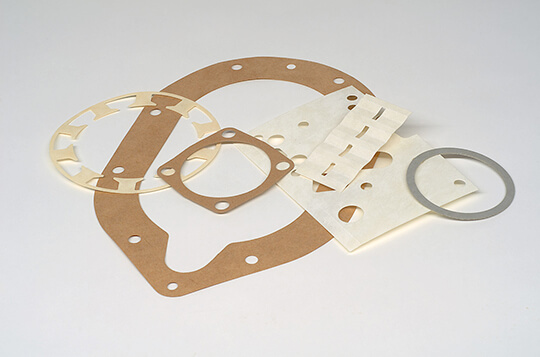

Fiber Gaskets & Materials

Fiber-based gaskets are one of the most broadly used categories of products. Fiber products can offer a very wide range of benefits and fit a wide range of applications.

This material is a cellulose plant fiber material that is impregnated with protein flue and binder, which typically consists of glycerin glue. This material is broadly used for gasketing. After it is treated, it is resistant to many oils, water, grease, gasoline and other solvents and chemicals. It is flexible and can conform to changes in the surface it is being applied to. Vegetable fiber can withstand operating temperatures of 250F.

Vulcanized fiber consists of cellulose and generally no binders or other additives. It is produced in different grades based on strength and other characteristics. This material is very hard, has high mechanical strength, good impact and abrasion resistance, has excellent electrical properties and is lightweight.

Fishpaper is the generic name of electrical grade vulcanized fiber. This material is commonly used for electrical insulation as it provides excellent arc resistance.

DuPont Nomex is an aramid fiber/insulation paper that offers excellent insulation properties. In addition, this material offers high inherent dielectric strength, mechanical toughness, thermal stability, flexibility and resilience. It offers electrical insulation and EMI protection as well as other benefits such as high radiation resistance, excellent UL rating, and high chemical stability.

There are a number of other commercial grade cellulose fiber / paper materials that are commonly used in general purpose gasketing. Vellumoid makes a line of these products that are popular choices, including Vellumoid 505. These products have general resistance to oils, water and certain other chemicals / solvents and have operating temp limits of up to 250F – 350F.

Ceramic fiber material is generally used for heat seals when high operating temps exist. This material can be engineered for different applications. Generally, it is soft, lightweight and can exist in temps over 2000F.

Copaco is a fiber / paper product that is made from high-grade cotton. It is extensively refined and has limited or no fillers and other binders. This ensures excellent aging characteristics. The material has a very high tensile and tear strength and has excellent dielectric properties.

Fiberboard is a cost-effective material that is typically used as a substitute for plastic. It is solid, water resistant, and environmentally friendly. It is used for barriers and other parts requiring stability.

Get Started with Your Custom Part

Contact UsFeatured Capabilities

- Minimal set-up

- High accuracy/finish

- Ideal for prototypes

- Minimal set-up

- High accuracy/finish

- Ideal for prototypes

- Efficient in processing different materials.

- Can accommodate for long run times and large part sizes.

- Equipment also has milling capabilities.

- Rotary die-cutting

- Hydraulic presses

- Punch presses

- Manual presses

- Programmable travel head presses

- From roll or sheet stock

- Minimal set-up

- Large parts - 36" x 54"

- Low tool cost

- Cuts solid rubber and sponge rubber

- Allows for production of OD / ID parts

- Efficient and High-Speed

- Excellent alternative to molding.

- Ability to vulcanize extruded rubber.

- Ability to vulcanize sponge rubber profiles.

- Accurate to .00005"

- 27 x 27 bed

- Used for all first and last piece inspection

- Accurate to .00005"

- 27 x 27 bed

- Used for all first and last piece inspection

- Cut thickness of material

- Cut width of material

- Coil material

- Apply adhesives