- Cut thickness of material

- Cut width of material

- Coil material

- Apply adhesives

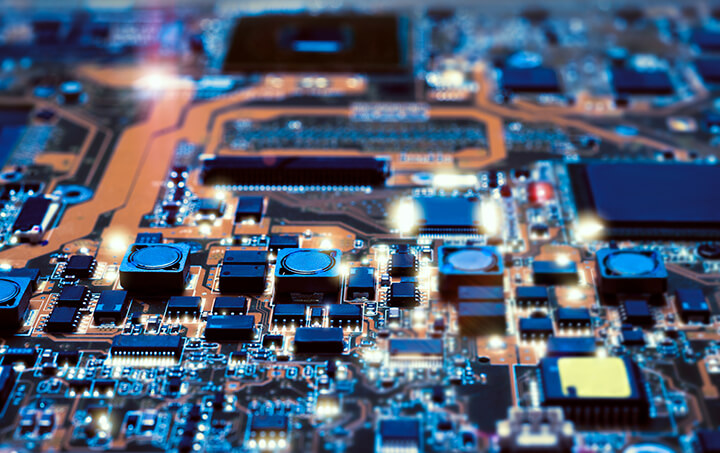

Thermostat and Electrical Enclosure Gaskets

We participate in selling gaskets that are used in industrial controls as well as thermostats. Generally, these gaskets are used around electronics or printed circuit boards, so there is often times very little room. In these cases, we frequently use thin (.015”) cloth-inserted rubber. This product withstands heat well and the cloth-insert provides stability. We have also used cork and rubber blends, plastic shim stock (Mylar) and sponge rubber blends for these applications.

Common Uses and Benefits Include:

Anti-Vibration Industrial Gaskets:

Any machine that produces frequency and vibration can benefit from the use of anti-vibration industrial gaskets. By effectively muffling vibration, the amount of wasted energy is significantly limited, and the risk damage caused by vibration is also reduced.

Industrial Gaskets for Sealing:

The most important function of a gasket is preventing leakages in an industrial system. These are often made from rubber due to its ability to block water and other substances.

Industrial Environmental Seal Gaskets:

These gaskets seal against dirt, dust and other small particles. Environmental seal gaskets are predominantly used in enclosures that protect equipment controls such as thermostats.

Industrial Gaskets for Mountings:

Modern equipment displays require protection from dust, shock and even liquids in order to ensure the integrity of sensitive digital display technology. Mounting gaskets made from the proper elastomer are well-suited for this application.

Common Materials

- Cloth-inserted rubber

- Cork and rubber blends

- Plastic shim stock (Mylar)

- Sponge rubber blends

Get Started with Your Custom Part

For more than 100 years, Excelsior has been providing personal service to a broad mix of customers. We are committed to being your reliable, one stop shop partner for standard and custom gaskets and seals. To request a quote or talk with our technical professionals about your job requirements, contact us at 815-987-2900.

Explore Our Capabilities

- Minimal set-up

- High accuracy/finish

- Ideal for prototypes

- Minimal set-up

- High accuracy/finish

- Ideal for prototypes

- Efficient in processing different materials.

- Can accommodate for long run times and large part sizes.

- Equipment also has milling capabilities.

- Rotary die-cutting

- Hydraulic presses

- Punch presses

- Manual presses

- Programmable travel head presses

- From roll or sheet stock

- Minimal set-up

- Large parts - 36" x 54"

- Low tool cost

- Cuts solid rubber and sponge rubber

- Allows for production of OD / ID parts

- Efficient and High-Speed

- Excellent alternative to molding.

- Ability to vulcanize extruded rubber.

- Ability to vulcanize sponge rubber profiles.

- Accurate to .00005"

- 27 x 27 bed

- Used for all first and last piece inspection

- Accurate to .00005"

- 27 x 27 bed

- Used for all first and last piece inspection

- Cut thickness of material

- Cut width of material

- Coil material

- Apply adhesives