- Cut thickness of material

- Cut width of material

- Coil material

- Apply adhesives

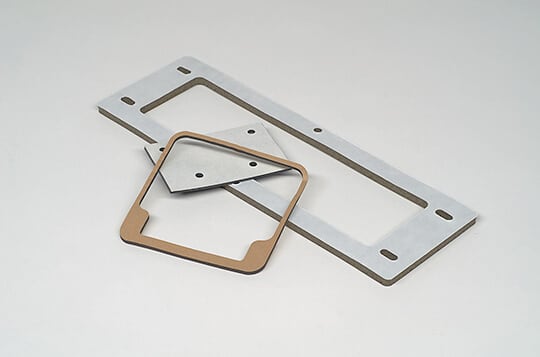

Pressure Sensitive Adhesive

Pressure Sensitive Adhesive (PSA) is commonly used throughout gasket applications. PSA can be used from a temporary means of holding a product in place during assembly to a more long-term permanent manner in which to bond 1 item to another. The most common types of adhesives used in gasketing applications are acrylic based and rubber based products. These products can be offered in "transfer" or "double coated" options.

Benefits of PSA Gasket Material

PSA is commonly applied to gasket material. In doing so, the exposed side of the PSA is applied to the gasket material and then ran through rollers that apply a nominal amount of pressure to bond the 2 together.

PSA is supplied and used in 2 different forms, including “transfer” and “double-sided” products. The amount of adhesive varies depending on the product. Most commonly used PSA’s have .001” - .005” of adhesive. The specific adhesive being used will vary in adhesion strength, dwell time, etc.

Transfer adhesives have 1 layer of adhesive on a release liner. Transfer adhesives are the most general-purpose and commonly used adhesives.

The Build-up of commonly used PSA's Transfer Adhesive:

- Adhesive - .002"

- Release Liner - .005"

Double-sided adhesives have 2 different layers of adhesive applied to opposite sides of a film carrier (ie .001” thick PET). This added carrier allows for additional stability during application and use. Using a double-sided adhesive also allows different types of adhesive and different thicknesses of adhesive on each side of the carrier. This can be beneficial depending on the end application.

- Adhesive - .002"

- Carrier - .001"

- Adhesive - .003"

- Release Liner - .005"

The common characteristics of both Acrylic-based and Rubber-based PSA's are:

| Acrylic based | Rubber based | |

| Moderate initial adhesion (gradual adhesion buildup) | High initial adhesion | |

| High shear strength | Moderate shear strength | |

| High temperature resistance | Moderate temperature resistance | |

| Excellent solvent resistance | Moderate temperature resistance | |

| Excellent UV resistance | Fair UV resistance | |

| Excellent durability | Moderate durability |

Get Started with Your Custom Part

Contact UsExplore Capabilities

View All Capabilities

- Minimal set-up

- High accuracy/finish

- Ideal for prototypes

- Minimal set-up

- High accuracy/finish

- Ideal for prototypes

- Efficient in processing different materials.

- Can accommodate for long run times and large part sizes.

- Equipment also has milling capabilities.

- Rotary die-cutting

- Hydraulic presses

- Punch presses

- Manual presses

- Programmable travel head presses

- From roll or sheet stock

- Minimal set-up

- Large parts - 36" x 54"

- Low tool cost

- Cuts solid rubber and sponge rubber

- Allows for production of OD / ID parts

- Efficient and High-Speed

- Excellent alternative to molding.

- Ability to vulcanize extruded rubber.

- Ability to vulcanize sponge rubber profiles.

- Accurate to .00005"

- 27 x 27 bed

- Used for all first and last piece inspection

- Accurate to .00005"

- 27 x 27 bed

- Used for all first and last piece inspection

- Cut thickness of material

- Cut width of material

- Coil material

- Apply adhesives